Use the right torque for the bolts

To allow the joints its maximum movement and to prevent damage to the rubber sphere, the bolts should be inserted

through the flange with the head of the bolts on the joints side.

No damage can come from the thread or nut.

To secure the joint to the pipe, the bolts should be tightened in the opposite pars applying the following torque:

| For

joints up to a diameter of 80mm |

60

Nm.(max) |

| For

joints bigger than 80mm |

80

Nm.(max) |

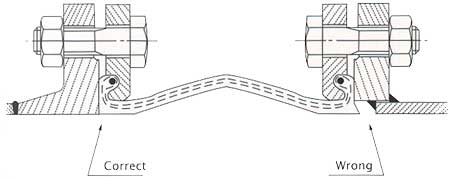

Use the right counter-flange

Use the right counter-flange for a proper connection and to obtain a durable and safe connection the following criteria should be met:

The innercliameter of the connecting flange and the rubber expansion jointshould be identical. The flange should be flat to ensure

maximum sealing and sufficient support for the flange

(see the above illustration), turbulence within the joint could cause

noise, pressure loss or even leakage at the connection.

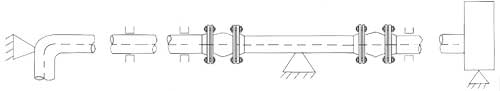

Installing the expansion joint

To install the expansion joints properly in the pipeline you should meet the following design criteria to prevent overextending

the expansion joints.

The expansion joints should preferably be placed directly after the anchor. There must be pipe-guides behind the joints to

support the pipeline.